UV protection solution: protect 3D print parts from sunlight

Screenshot youtube.com

Screenshot youtube.com

The ultraviolet (UV) Radiation represents a significant and should not be underestimated danger for the longevity and quality of 3D printed components. Especially in applications where the printed components are permanently exposed to sunlight, the properties of the materials can be significantly impaired. The UV radiation can have the mechanical propertiesof the components, impair their aesthetic characteristics and significantly limit functionality over time. This threat is particularly relevant for plastics that are widely used in additive manufacturing, as they are prone to discoloration, material fatigue and other damage if exposed to direct sunlight for a long time.

Challenges of UV radiation in plastics in additive manufacturing

Plastics used in 3D printing technology often show a number of problems with prolonged UV exposure. This includes discolouration that reduces the visual attractiveness of the components, as well as material fatigue, which impairs structural integrity. These effects cause the components to become more brittle over time and lose their mechanical properties.It is therefore essential to take measures to minimize the harmful effects of UV radiation, especially in outdoor applications, in the production of prototypes or long-lasting components.

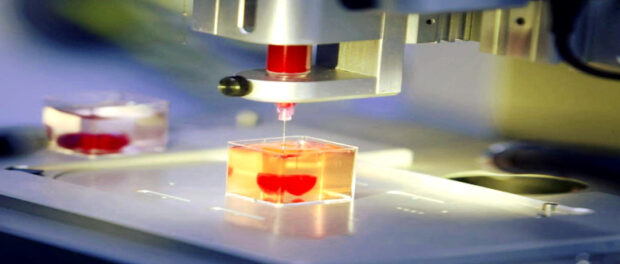

UV and weather resistant filaments: A solution in the manufacturing process

To effectively counter these problems, special filaments are on the market, which are already provided with UV and weather-resistant additives in the manufacturing process. These special materials contain ingredients that significantly reduce the penetration depth of the UV rays into the interior of the printed object. This integrated protective function ensures long-term stabilityThe components preserved, both in terms of their mechanical properties and their visual appearance. Such filaments are a sustainable solution, as they guarantee basic protection during the printing process and thus offer permanent resistance to UV damage.

Subsequent impregnation and coatings: alternatives to protection

In addition to using special filaments, there is also the possibility of providing already printed 3D parts with UV-protective coatings or impregnations. These coatings act as a barrier against harmful UV rays and protect the material from discoloration and material fatigue. In addition, they often improve the surface quality of the components byCreate smoother and more even surface and thus increase the aesthetic value of the object. These subsequent treatments offer the advantage of being flexibly applied to existing parts without having to change the actual printing process.

Decision criteria for optimal UV protection

The choice between using a special UV-resistant filament during the printing process or a subsequent coating depends on the specific requirements of the respective project. Factors such as the application environment, the expected exposure to UV rays, costs and the desired optical properties play a decisive role in the selection ofsuitable protective measure. For long-lasting outdoor applications, the combination of both approaches is often recommended to ensure maximum protection.

Protective measures for longevity and functionality

In any case, it is of central importance to choose a suitable solution to effectively prevent the negative effects of UV radiation. The targeted use of UV-resistant filaments or subsequent coatings can significantly reduce fading, cracking and structural damage. This means that the longevity and the functional integrity of the3D printed components are sustainably secured, which is particularly important for durable constructions, outdoors or visible components. The right protection strategy thus makes a decisive contribution to significantly increasing the quality and service life of the printed products.